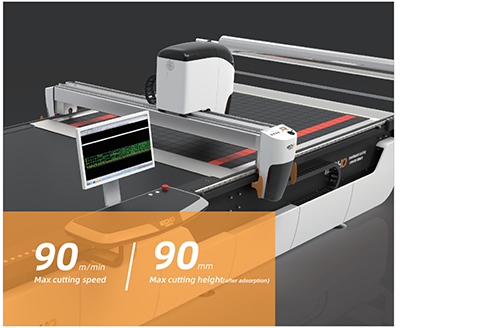

GLSC Automatic Multi-layer Digital Cutting Machine for Mass Production

Features

- Advantages of Digital Cutting

- New Vacuum Chamber Design

- Automatic Knife Wear Compensation

- Fully Automatic Continuous cutting function

- New Intelligent sharpening system

- Catalouge of GLSC Automatic multi-ply cutting system

- Video of GLSC Automatic multi-ply cutting system

- Video of GLSC cutting upto 8cm of Knitwear Material

- Video of GLSC cutting upto 100 Layers of Kuqi Fabric

- Video of GLSC Cutting Machine for Denim 80Plies

- Video of GLSC Cutting Machine for Polyfill

- Improves Production Volume.

- Increases overall throughput.

- Improves Material Utilization.

- Improves Production Management with Smart & Connected Systems.

- Low Cost of Ownership.

- Perfect Cut Quality with Precision.

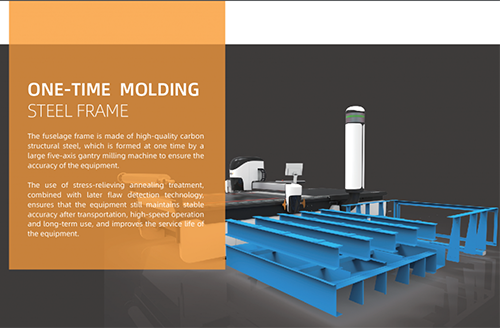

- Optimized Cavity Ventilation Airways.

- Intelligent Sensors Reduce Vacuum Leakage.

- Reduces Power Consumption.

- Knife Wear Compensation Factor is Added & Will Improve Cut Quality.

- No Pause between bites.

- Throughput improvement by more than 30%.

- Long Patterns can be cut in single window.

- No human intervention is required during cutting.

- Swiss imported high-speed sharpening motor can automatically adjust the number of sharpening revolutions according to cutting requirements, making the blade sharper which yields precise cut

- Sharpening Belt lowers the cost of ownership

- Predictive sharpening belt system

- Multi angle sharpening approach based on the characteristics of the fabric

- Quick change sharpening belt reduces maintenance time

- Catalouge of GLSC Automatic multi-ply cutting system

- Documented video of Automatic Multi-Ply Fabric GLSC Automatic Multi-Ply Cutting System

- Documented video of iECHO GLSC Automatic Multi-Ply Cutting Machine can cut upto 8cm of Knitwear Material.

- Documented video of iECHO GLSC Automatic Multi-Ply Cutting Machine can cut upto 100 Layers of Kuqi Fabric.

- Documented video of iECHO GLSC Automatic Multi-Ply Cutting Machine for Denim 80Plies

- Documented video of iECHO GLSC Automatic Multi-Ply Cutting Machine for Polyfill.

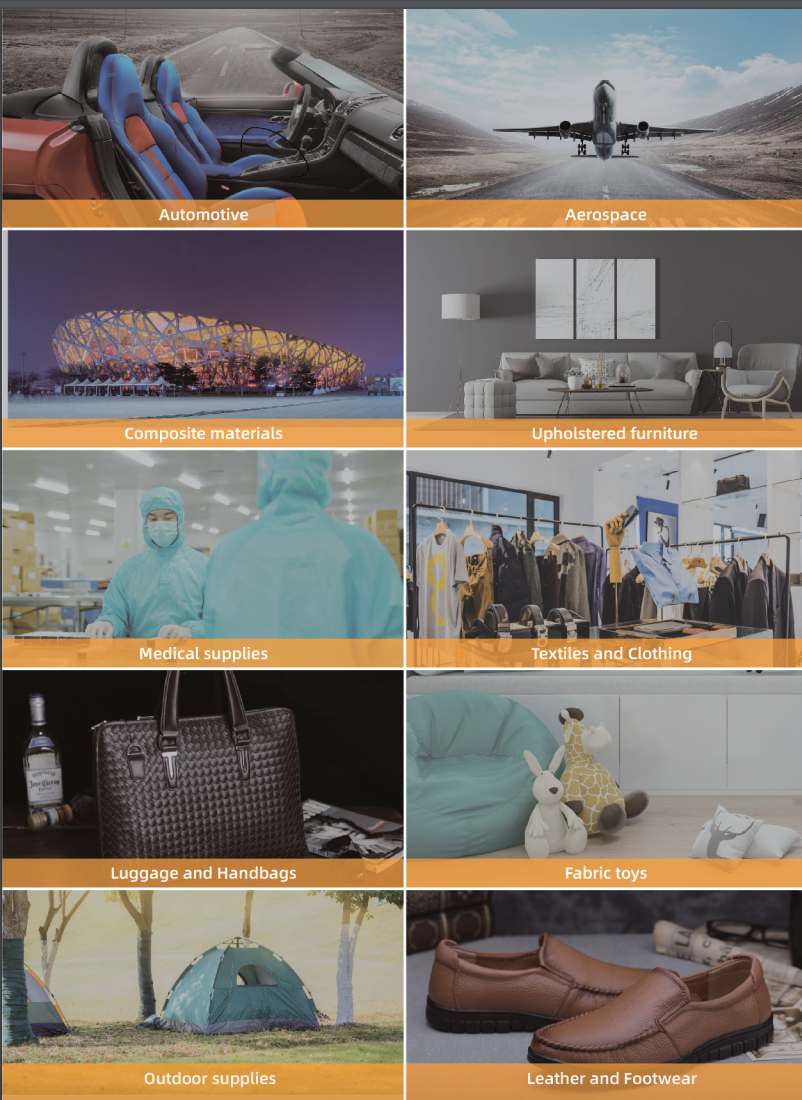

Application

GLSC Automatic Multi-Ply Cutting System can be used in mass production environment of Apparel, Footwear, Health Care Products, Home Furnishing &

Automotive interior.

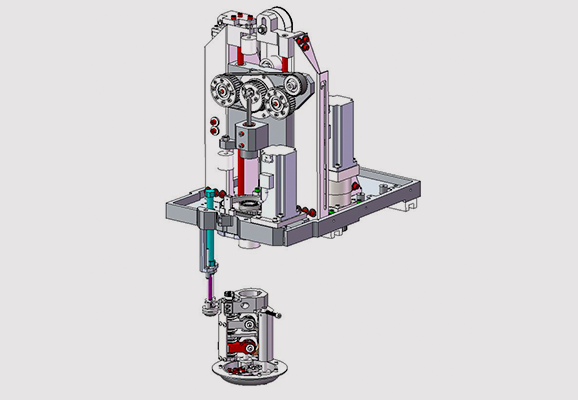

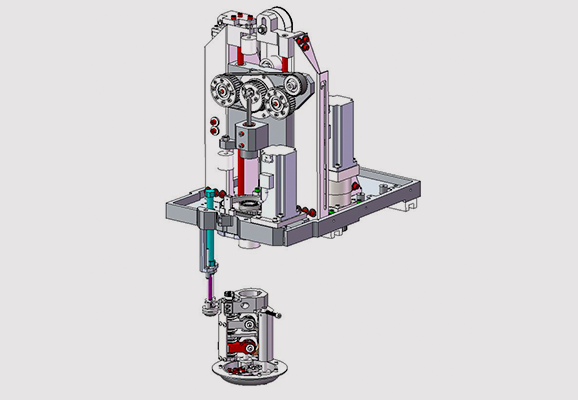

GLSC is equipped with iECHO’s high speed Electronic Oscillating Tool (EOT), can cut soft materials with high speed, high precision and high intelligence. IECHO CUTSERVER Cloud Control Centre has powerful data conversion module, which ensures GLS work with the mainstream CAD software in the market.

×

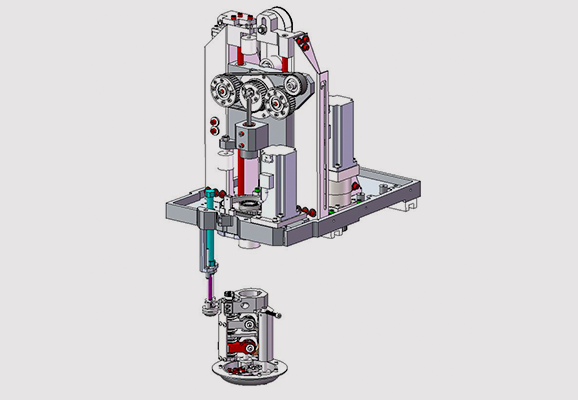

High Frequency Oscillating Tool @ 6000 rpm is suitable for cutting material of medium & high density using different kind of blades Quick change sharpening belt reduces time for maintenance The knife is as sharp on its last cut as its first cut Standard dual drill & optional 3rd drill can handle up to 16mm drill bit depending upon fabric

High Frequency Oscillating Tool @ 6000 rpm is suitable for cutting material of medium & high density using different kind of blades Quick change sharpening belt reduces time for maintenance The knife is as sharp on its last cut as its first cut Standard dual drill & optional 3rd drill can handle up to 16mm drill bit depending upon fabric

Tools