GLSA Automatic Multi-layer Digital Cutting Machine for Mass Production

Features

- Improves Production Volume.

- Increases overall throughput.

- Improves Material Utilization.

- Improves Production Management with Smart & Connected Systems.

- Low Cost of Ownership.

- Perfect Cut Quality with Precision.

- Prevents Vacuum Leakage.

- Reduces Power Consumption.

- Improves Cut Quality due to better Vacuum Stability.

- Knife Wear Compensation Factor is added Automatically as the knife wears out thereby providing Perfect Cut quality with Precision Cut.

- iECHO GLSA Automatic Multi-Ply Cutting System Catalogue

- iECHO GLSA Automatic Multi-Ply Cutting System Documented Video

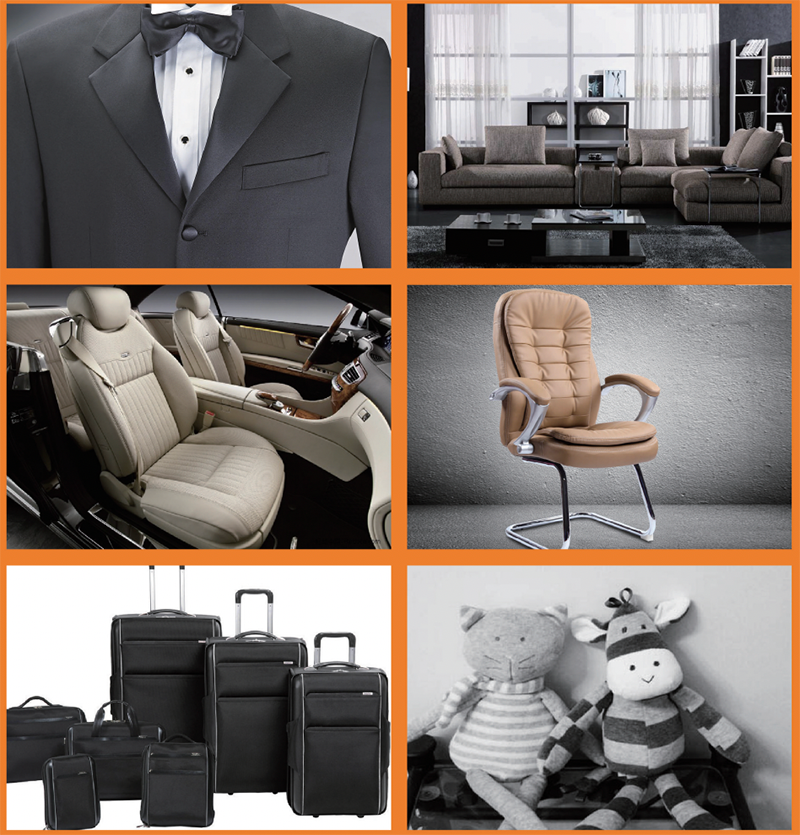

Application

GLS Automatic Multi-Ply Cutting System can be used in mass production environment of Apparel, Footwear, Health Care Products, Home Furnishing & Automotive interior.

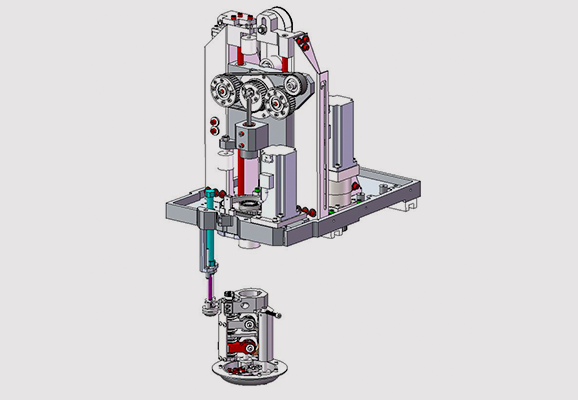

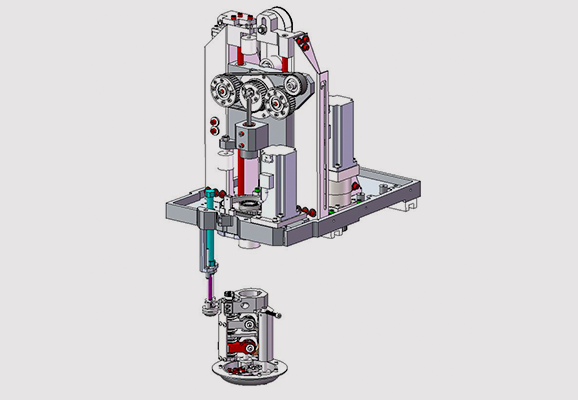

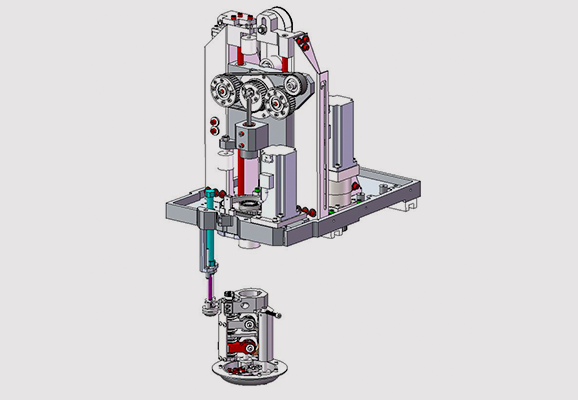

GLSA is equipped with iECHO’s high speed Electronic Oscillating Tool (EOT), can cut soft materials with high speed,high precision and high intelligence. IECHO CUTSERVER Cloud Control Centre has powerful data conversion module, which ensures GLS work with the mainstream CAD software in the market.

×

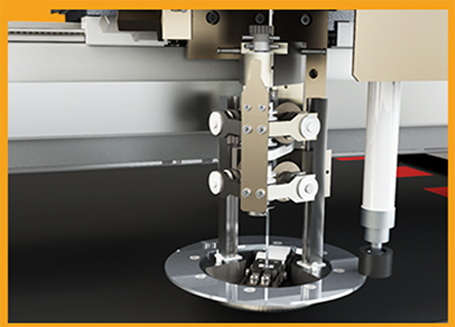

Electrical Oscillating Tool @ 4500rpm is suitable for cutting material of medium & high density using different kind of blades Quick change grinding stones reduces time for maintenance Sharpens at the same angle regardless of knife or stone wear The knife is as sharp on its last cut as its first

Electrical Oscillating Tool @ 4500rpm is suitable for cutting material of medium & high density using different kind of blades Quick change grinding stones reduces time for maintenance Sharpens at the same angle regardless of knife or stone wear The knife is as sharp on its last cut as its first

Tools

System

- Modern GUI with sleek user interface.

- User Friendly Icons, Reports, Graphics.

- Production visibility: Operational improvement & efficiency gains!

- Reduced downtime: easy-to-access remote service capabilities & error monitoring!

- Consumable’s replenishment: get the parts you need, when you need them!

- Data: IECHO's way to provide you your production information directly to you!

- Adjust the knife angle based on pressure, material properties, X-Y Speed, Reciprocating rpm

- Smart Vacuum System reduces energy consumption by 20% while providing superior material stability.

- Adjusts vacuum levels based on what’s being cut.

- Intelligent sensors monitor vacuum pressure and adjust according to the requirement

- Blows cold air on to the knife, keeping it cool.

- Prevents fusing between material plies and adjacent parts.