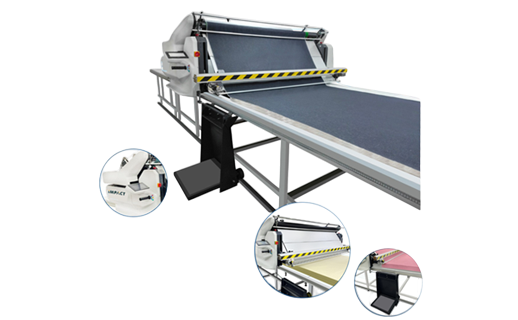

iMPACT Automatic Fabric Spreading Machine

Features:

Tension-free spreading

- Tension-free spreading ensures more accurate cut pieces and lower rejection rate in the sewing room.

- Automatic cutting device.

- Different speed options in different ways.

- Stops automatically when no Fabric sensor is activated and automatically returns to origin for fabric loading.

- Automatic Fabric Threading increase productivity.

- For Elastic material, angle adjustable bar with curve design for wrinkle free spreading.

- Fabric feeding system with conveyor belt and servo motor.

- Ability to lay fabrics precisely without stretching.

- Ability to lay roll and open rested fabrics.

Automatic Fabric Relaxing system

- Automatic Fabric Relaxing system ensures high quality spread for elastic material.

- Ply counter.

- Programmable lay length and end allowance settings.

- Operator-side safety device.

- Face-up, one way.

- Face-to-face (or zigzag).

- Flat-fold attachment.

- Smoothing roller.

- Remote emergency stop.

- Operator platform.

- Plc system, easy to use touch control screen.

- Fabric laying width between 1.60cm-2.20cm.

Automatic edge shifting device

- This device can perfectly solve the edge curling problem in knitted fabrics which helps to utilize maximum fabric width.

Automatic Servo feeding

- Servo automatically follows the transmission device of cloth feeding roller and precisely matches with the main servo thus perfectly enabling tension-free fabric spreading. It intelligently and automatically adjusts the tightness and the edge to edge spreading accuracy.

Technical Specification

| Laying height with zigzag apparatus | 20 cm |

| Maximum laying speed | 105 mt / minute |

| General machine weight | 460 kg |

| Electrical requirement | 220 v ac 50 hz 4 kw |

| Standard roll dimension | 50 cm |

| Standard roll weight | 70-150 kg |

| Standard laying width | 160 cm - 220 cm |

| Standard laying height | 25 cm |

| Zigzag laying height | 20 cm |