LCKS Digital Leather Furniture Solution

Precisely Cut Parts/ Outstanding Thoughput / Maximum Yield / Efficient Design / Intelligent Management System

Features:

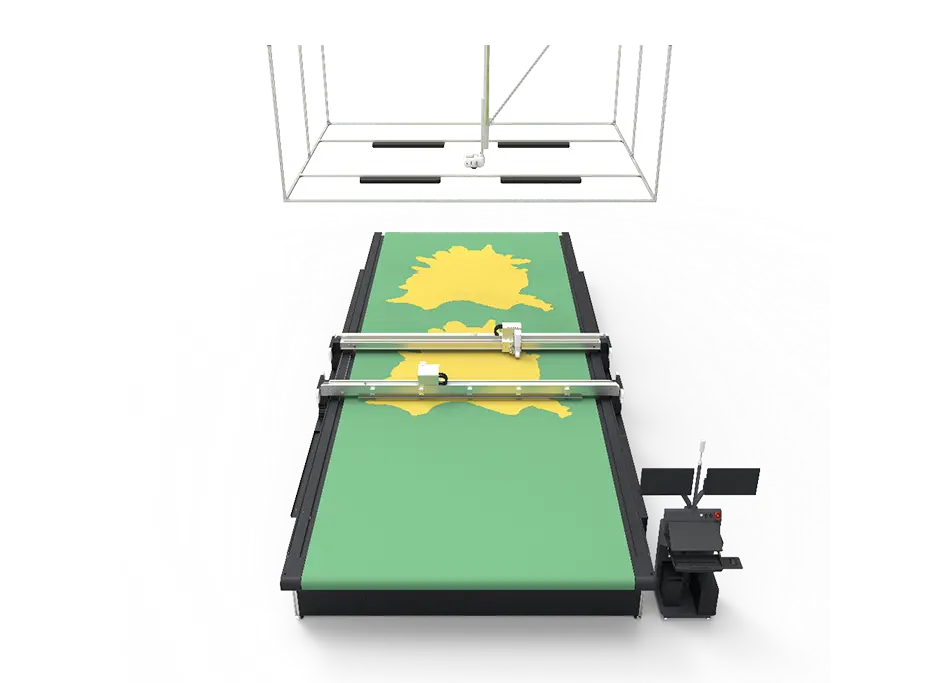

Production line work-flow

12mm steel frame with qualified connection technology, the machine body frame weighs 600KG. Strength increased by 30%, reliable and durable.

Maximize cutting time

LCKS cutting line can be processed continuously, which can improve the effectiveness to 75%-90%.

High quality imported felt with good color contrast

Material can be fixed well with strong felt friction to reduce the leather recognition time and improve cutting accuracy.

Infrared safety device

Safety protection device with high sensitive infrared sensor, can ensure the safety of person and machine.

System

Leather automatic nesting system

- Complete the nest of a whole piece of leather in 30-60s.

- Increased leather utilization by 2%-5% (The data is subject to actual measurement).

- Automatic nesting according to the sample level.

- Different level of defects can be used flexibly according to customer requests to further improve the utilization of leather.

Order management system

- LCKS order management system runs through each link of digital production, flexible and convenient management system, monitor the whole assembly line in time, and each link can be modified in the production process.

- Flexible operation, intelligent management, convenient and efficient system, greatly saved the time spent by manually orders.

Assembly line platform system

LCKS cutting assembly line including the whole process of leather inspection - scanning - nesting - cutting- collecting. Continuous completion on its working platform, eliminates all traditional manual operations. Full digital and intelligent operation maximizes cutting efficiency.

Product Parameters

LCKS1 PARAMETERS

| Cutting Machine Size | 5000mm x 4500mm |

| Cutting Types | Genuine Leather / Roll Leather |

| Cutting Dimension | 25-70 Square Feet |

| Cutting Efficiency | 8 min / Piece |

| Staffing | 👤👤 |

| Cutting Tool | 1 Set |

| Machine Power | 15 KW |

LCKS3 PARAMETERS

| Cutting Machine Size | 11400mm x 4500mm |

| Cutting Types | Genuine Leather |

| Cutting Dimension | 25-70 Square Feet |

| Cutting Efficiency | 3 min / Piece |

| Staffing | 👤👤👤 |

| Cutting Tool | 2 Set |

| Machine Power | 30 KW |

* The product parameters and functions mentioned on this page changed, will not further notice.

APPLICATION

LCKS digital leather furniture cutting solution, from contour collection to automatic nesting, from order management to automatic cutting, to help customers accurately control each step of leather cutting, system management, full-digital solutions, and maintain market advantages.

Utilize the automatic nesting system to improve the utilization rate of leather, maximum save the cost of genuine leather material.Fully automated production reduce dependence on manual skills. A fully digital cutting assembly line can achieve faster order delivery.